Relaunch of RIGIPS Heaquarter

Project description

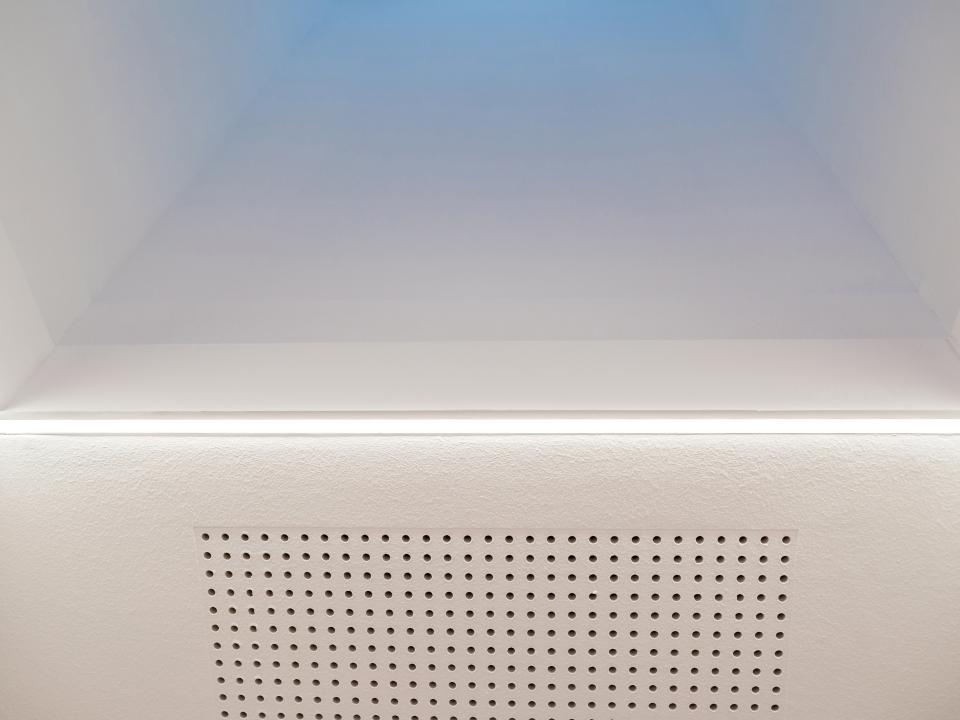

The entrance hall makes the first impression of any company. The structural redesign of the outdated office and reception area at the RIGIPS headquarters was intended to give the head office in the Styrian town of Bad Aussee a new, fresh appearance. The design reveals an insight into the design options of the creative dry lining. Simultaneously, the best possible use was made of the material’s added value and the significant improvement of the structural parameters – especially with regard to acoustics and indoor air quality. The two-man installers team had just 17 days to complete the entire conversion. In the formerly dark corridors the acoustics were improved and the lighting was fundamentally reorganized – combining daylight and energy-saving LEDs. With the curved Rigitone BIG Curve ceiling construction in the staircase a characteristic architectural highlight was added to the entrance.

Contractor

Abel & Knechtl Trockenbau OG

For Abel & Knechtl, being a dry lining master means having the courage to go beyond your own knowledge and try out new things in addition to the standard works. This is the daily challenge for the two entrepreneurs. In 2014, they started their own business with 20 years of experience. They consciously decided to stay “small”. The company stands for quality, reliability and fair pricing. They also pass on their knowledge. The two businessmen teach at the Master School for plasterers and drywall installers, which is also lead by Gerhard Abel.

Key Achievements

- The view of daylight was significantly increased by opening up the existing skylights and installing the funnel-shaped drywall extensions. This not only creates a friendly room atmosphere, it also reduces the cost of energy for lighting.

- Close cooperation between the installation team and the technical department of RIGIPS made it possible to efficiently plan and implement the extreme radii of the curved ceiling. The curved LED profiles were developed in cooperation with the manufacturer.

- The short construction time and the execution of conversion work during normal operations were a huge challenge to the installers. The stairwell was closed off throughout the construction period due to the installation of scaffolding. Employees were directed to a different stairwell.

Key Challenges

One of the greatest challenges for the installer alongside the short construction and installation period was the detailed execution plan for the architect’s design. The dry lining experts were supported on-site by the RIGIPS technical department, even with drawing up the installation plans for the curved concave and convex ceiling elements. In addition to the difficult task of accurately implementing the extreme radii of the ceiling, they also had to come up with a solution for indirect lighting with the curved LED profiles. For that they developed and implemented a customised solution in coordination with the manufacturer. Because of the indirect LED lighting in the corridor area a strict demand on the quality of the surface arose – only a Q4 quality level finish would suffice. The edges – especially those adjacent to the doors – also had to be exact and impact-resistant.