Carls Tower

Project description

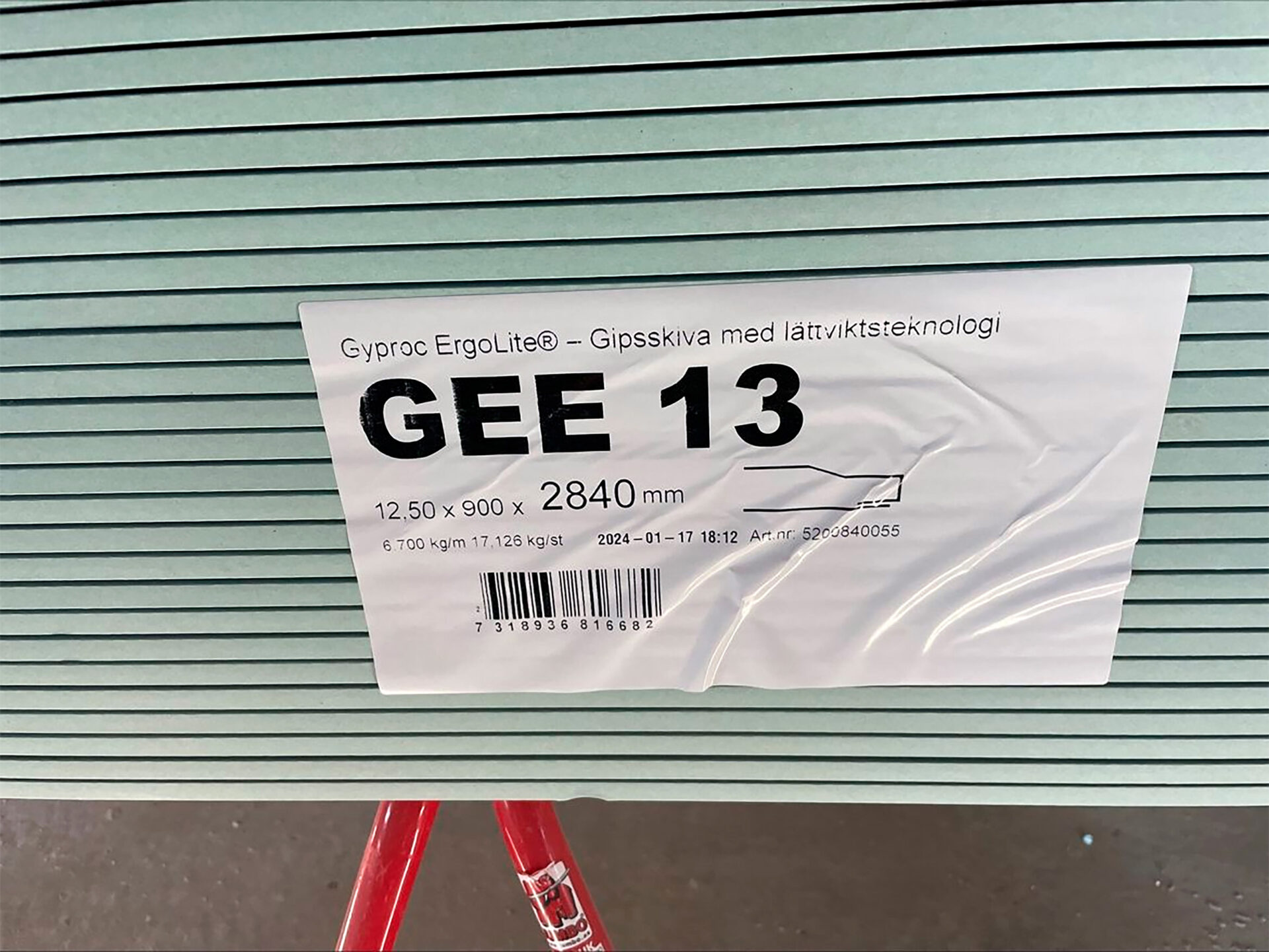

Carls Tower in the area of Carlsberg Byen in Copenhagen is a prestigious building rising 80 meters, housing retail in the lower floors and apartments from floor 5 to 23. An innovative solution was needed in Carls Tower to complete this ambitous project. Gyproc® has supplied internal walls and suspended plasterboard system (ceilings) made of GEE Ergolite and ER steel.

Main information

80 m² height, 31.400 m²

Retail and apartments

Udviklingsselskabet Carlsberg Byen P/S

Vilhelm Lauritzen Arkitekter A/S

Contractors

Pihl A/S

Company name: Pihl A/S

Main Representative: Martin Kofoed Led, Senior Project manager

Number of collaborators: 350

Specialties: Turnkey contracting, Renovation, Newbuild

Founded in: 1887

Biography: Pihl A/S is competent general, main or management contractor, focused on implementing and optimizing projects within new build and renovation. Pihl’s knowledge is built on a proactive approach and 130 years of unique history.

Pihl is a Danish-owned contractor with a creative and innovative mindset, and experience from numerous high level projects: Among others, several of Denmark’s most challenging iconic buildings such as the Opera house, the Drama House, FN Byen, Denmark’s Rock Museum ‘Ragnarock’ and Carlsberg Byen.

Website: www.pihl-as.dk/da/

Key Challenges

-

Logistical Packaging per Floor: The requirement for logistical packaging to be organized floor by floor.

-

Tower Movement due to Wind: The tower experiences both horizontal and vertical movement caused by wind, necessitating walls capable of telescoping in the same directions.

-

Waste and Cut-Off Optimization: Reducing material waste and optimizing cut-offs during the process.

-

Limited Installation Height for GK System: Working within the constraints of a limited installation height for the GK system.

Key Achievements

-

Optimized On-Site Logistics: Developed special packaging that was subsequently lifted onto each floor.

-

Horizontal and Vertical Telescoping Solutions: Designed a solution allowing walls to telescope both horizontally and vertically to accommodate wind impact on the tall tower.

-

Customized Materials to Minimize Waste: Delivered specially lengths of Ergolite and steel to minimize waste and streamline workflows.

-

Modification of GK28 Mounts: Modified and adjusted the GK28 mounts to compensate for the limited ceiling height.

Sustainability in the project

- The use of ErgoLite not only meant a tangible, positive impact on the workload for the builders, it also meant wall heigh could be obtained without joints.

- Deliveries were packaged and delivered in a ready package for each floor improving logistics for the contractor.