Emaar Square Mall

Project description

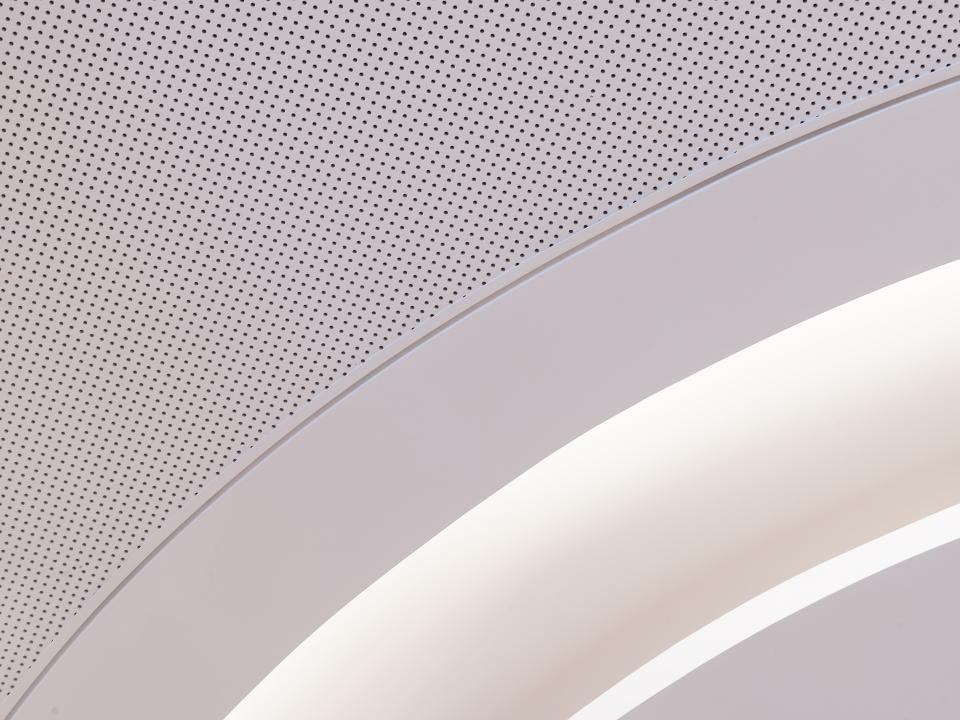

Emaar Square Mall is a part of the “Emaar Square” project along with residential units, offices and a hotel forming a complete development. Emaar Square takes its name from the wide and historical squares of Istanbul that unite people and lifestyles, having been envisioned to become a social hub. It has a strategic and central location on the Asian side of Istanbul with a convenient access from the main highways of the city. Being a shopping mall, acoustics was one of the main concerns. High occupancy rate, large volumes, high ceilings and floor openings made the use of materials with good acoustic performance a must. RIGITONE® acoustic ceiling boards were chosen by the contractor for a controlled acoustic environment and good sound absorption. Successful application by the contractor has also led to a monolithic appearance resulting in a highly aesthetic finish for curvilinear planes.

Contractor

Celikeller Dek. Yapi Sist. San. ve Tic. Ltd. Sti.

Celikeller is a family-owned company which was founded in 1993. Since then, it has been an active contractor of different dry construction system manufacturers. Celikeller has completed more than 2000 national and international prestigious applications. It has proved itself to be a major contractor in the Istanbul region with successful plaster, drywall and suspended ceiling applications by its experienced team. It also has been manufacturing plasterboard wall and ceiling accessories, aluminum profiles and access panels.

Key Achievements

- On-time implementation thanks to the logistics of Rigips Turkey and hard work of the whole team

- Time and cost efficiency of RIGITONE® by having good acoustic, fire retardation and aesthetic performance altogether

- Good cooperation within the team

- Making the customer ask for NRC values and eliminating the biggest competitor like this due to their failure to provide them

- Delivering on-site solutions for a wide range of application details

- Contribution to LEED certification (LEED Silver candidate)

Key Challenges

- Very tight schedule in order to compensate the delay caused by previous construction & application works

- Harder installation process due to extensive substructure

- Demand for seamless finishes while working with curvilinear surfaces

- Use of metal framework for the acoustic ceilings instead of hollow section structures which were used elsewhere