Project description

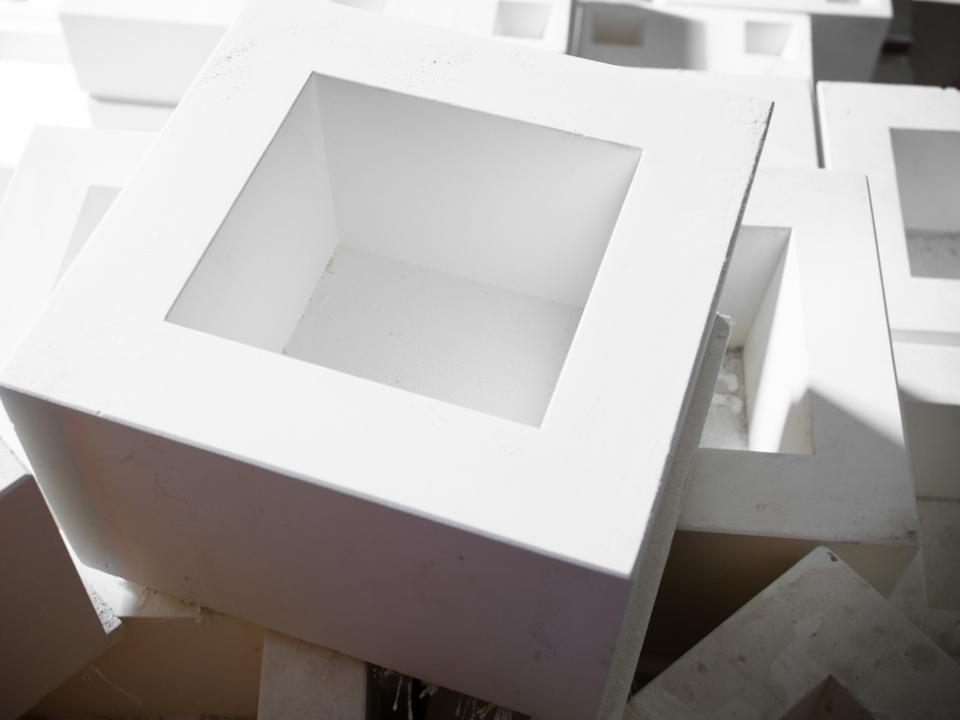

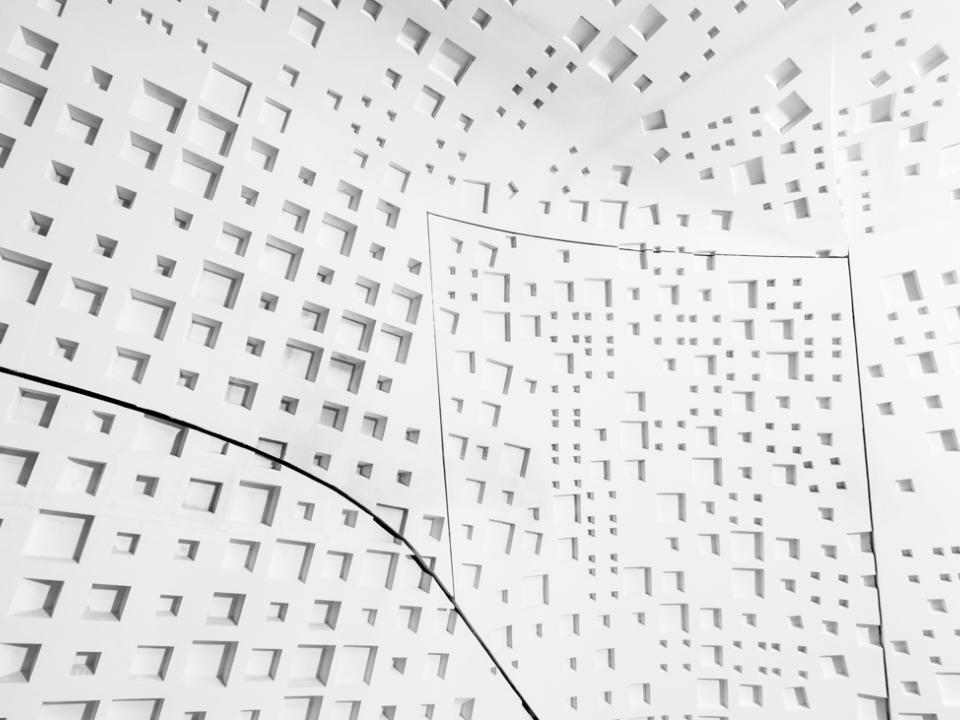

The Philharmonie de Paris opened its doors in January 2015. The project presented concerns the Symphonic Hall, known as the “Grande Salle”: a state-of-the-art facility for national and international symphony orchestras. The Symphonic Hall is a remarkable architectural feat; an ‘enveloping’ auditorium with a capacity of 2400 seats, that immerses the audience providing a uniquely intimate listening experience. The acoustical program called for great clarity of sound combined with high reverberation, as well as significant lateral reflections and a close, intimate feeling. The solution was found in a daring system of floating balconies which creates the intimacy, and the outer shell, which produces the high reverberation. Ile de France Plâtrerie had been commissioned to realise the outer shell of the Symphonic Hall, a completely dissymmetric structure made of plaster, up to 26 metres high, 10cm thick, and including 5785 cubic sound absorbers of fibrous plaster.

Contractor

Ile de France Plâtrerie

Ile De France Plâtrerie is a family-owned business. They were originally a traditional plasterer, but have diversified their activity towards all types of plaster works (including fibrous plaster, plasterboard etc.) and have concentrated more and more on highly complex projects. Over the years, they have developed a unique know-how and have positioned themselves on exceptional and atypical projects, pushing the limits of well-established techniques & methods; this is the way IDFP are differentiating themselves from their competitors.

Key Achievements

- A great clarity of sound combined with high reverberation were obtained thanks to the combination of the massiveness of 100 kg/m² of plaster and the principle of 3D sound through the integration of 5785 fibrous plaster modules.

- The manually implemented fibrous plaster cubes (7 different shapes), following a precise pattern, are offering the Symphonic Hall great esthetics and a unique signature of the architect.

- The mechanical resistance & integrity, as well as the fire resistance level of the system (10 cm of plaster, over a height of 20 m using Placostil ® M70 studs), were approved by the CSTB via a Technical Assessment (ATEx)

Key Challenges

- Acoustics: 100 kg/m² of massiveness of the plaster walls required (on a height of 20 m).

- Aesthetics: a unique pattern of 5785 fibrous plaster cubes had to be integrated into the plaster.

- A completely innovative process, in terms of both acoustics and aesthetics, which needed to be approved first.

- A very tight deadline: 25 plasterers working on the project, working 24h/day (even on Sunday) to be able to deliver the project on time.